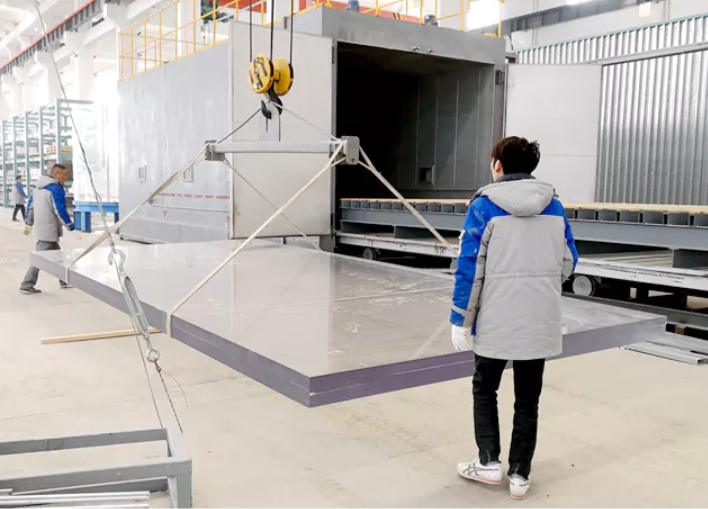

ANNEALING

We will anneal all acrylic products that require machining. This is because the material stress of the acrylic sheet increases during machining. Standard procedure for annealing Acrylic Products: Acrylic annealing only in a temperature-controlled convection oven The annealing temperature must be below the material-specific softening / melting point (80 ° C for cast acrylic) During annealing, the temperature must be kept as constant as possible and air circulation must be ensured on all sides within the furnace. A slow, steady increase in temperature and keeping the temperature constant over a comparatively long period of time. A very slow, even cooling is also decisive for the success of the annealing Annealing intervenes in the molecular structure of the acrylic: Molecular lattices that are "mixed up" during processing are reorganized, which releases the internal tensions. So that the acrylic retains these positive properties even after annealing, orderly cooling is important: The acrylic products should only be removed from the oven at below 50 ° C and then slowly continue to cool down at room temperature. Before further processing, all acrylic workpieces must therefore be tempered in order to free them from material tension.

Need Custom Pool or Aqua Acrylic?

Free Sample on Request

30 Years Warranty

Lead Time in 7-10 Days